Nondestructive 3D inspection of parts with internal structures

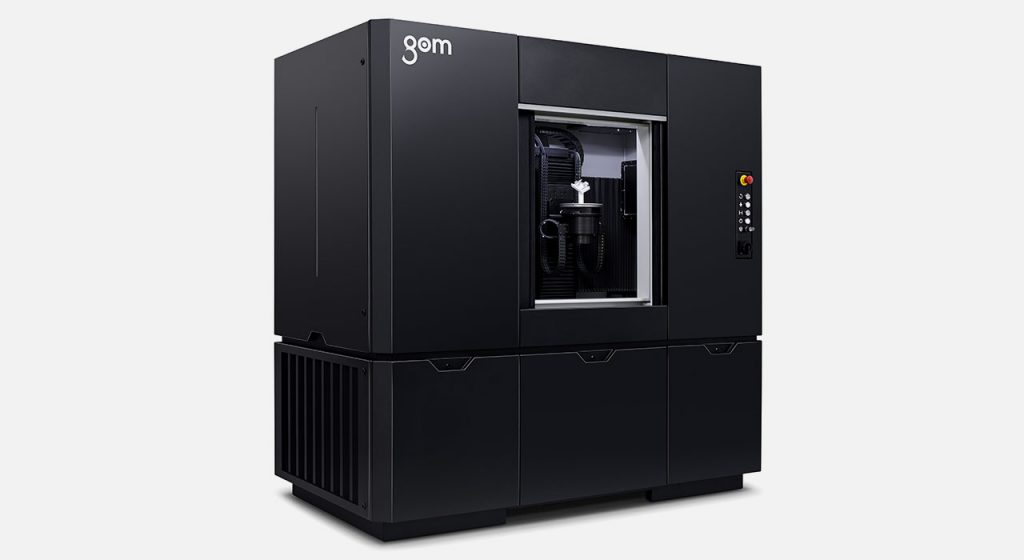

The GOM CT digitizes complex parts including the internal geometries at the finest level of detail. You get a complete 3D image for GD&T analyses or nominal-actual comparisons. The metrology CT particularly excels in digitizing small plastic and light metal parts.

Extremely high resolution

thanks to a 3k X-ray detector (3008 x 2512 pixels)

High precision

due to mathematical modeling of the measuring room

Automatic object positioning

via 5-axis kinematics and live view in the software

All-in-one software

for a consistent, fast workflow

RESOLUTION

Reveals what remains hidden with other systems

When digitizing a part, the GOM CT achieves an outstanding sharpness of detail: On the one hand, because it uses a high-resolution 3k X-ray detector for acquiring measuring data and on the other hand, because each part is measured in the best possible measurement position and thus always in the highest possible resolution. You can see the result below: on the left, measuring data generated with the GOM CT and on the right the usual standard.

The GOM CT generates high-resolution measuring data that show every detail: The pictured part (total diameter: 1 cm) was taken out of an in-ear headphone and digitized with GOM CT. The diameter of a single grid element is 0.1 mm.

PRECISION

Guarantees high precision

For producing its precise 3D measuring data, GOM CT applies mathematical intelligence: It combines perfectly interconnected algorithms throughout the measuring sequence with digital modeling of the measuring room. Additionally, the system features optimized mechanical stability of all components that are relevant for performing the measurement. The bottom line: Based on the measuring results, you can evaluate a part’s quality in a truly reliable, highly precise way and conduct further analysis.

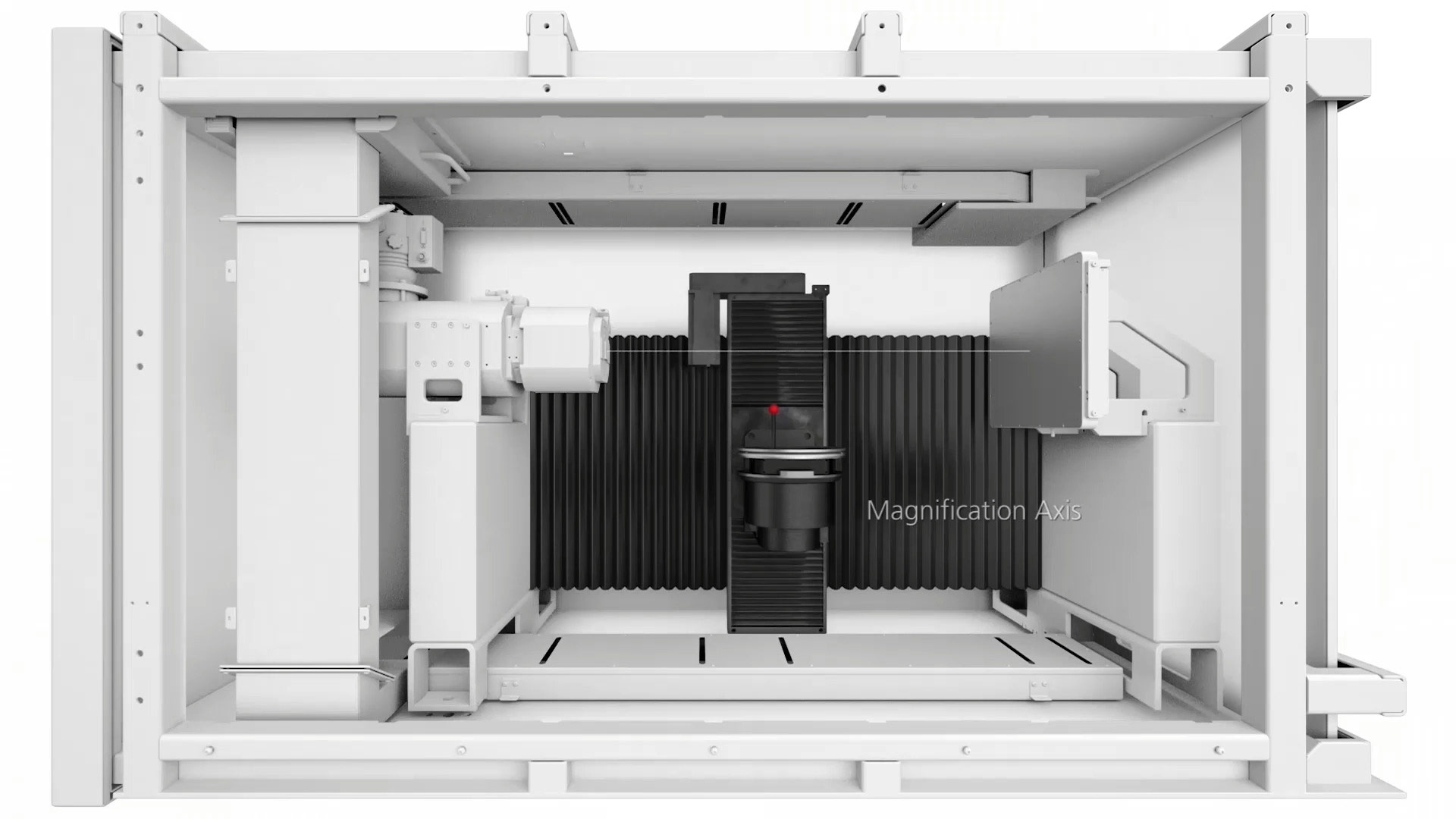

AUTOMATIC OBJECT POSITIONING

Easy centering of the part

A 5-axis kinematics with integrated centering table helps you to optimally position the part in the measuring volume. You simply place it in the machine’s measuring room – the rest is done by the software.

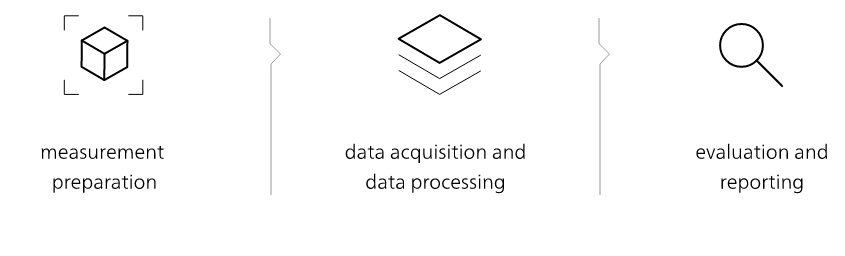

WORKFLOW

Highly automated metrology solution

A CT system is only suited for inspection during production if it can be operated by workers without expertise in computed tomography. Both the measurement and the evaluation of the measuring data should run automatically. At the same time, the CT system must achieve high throughput. GOM has come up with a smart workflow for this.

SOFTWARE

All-in-one software

The control of the device and the metrological evaluation of the data are combined in a single software package, making additional software or intermediate steps redundant. The process chain from the recording of the raw data through the inspection up to the creation of a measuring report is significantly simplified.

Technical data

| X-ray source | 225 kV |

| X-ray detector | resolution: 3008 x 2512 pixels |

| Measuring area | Ø 240 mm h: 400 mm |

| Voxel size | 2 µm – 80 µm |

| Dimensions | H. 2210 mm W. 2200 mm D. 1230 mm |

| Weight | 4800 kg |

| Fields of application | first article inspection, tool correction, inspection during ongoing production |

| Inspection features | internal structures, wall thickness, material defects, pores and shrinkage cavities |

| Measurement tasks | GD&T analysis, nominal-actual comparison, assembly analysis |

Metrology CT – suitable for the shop floor

info@ucs-int.com

+92-337-7779040

+92-336-9212968

Location

UCS Tower, plaza # 1, Hill Road Commercial area , phase 6 , Bahria Town, Islamabad Pakistan

About us

The Pakistans leading 3D Printing Service & Marketplace!